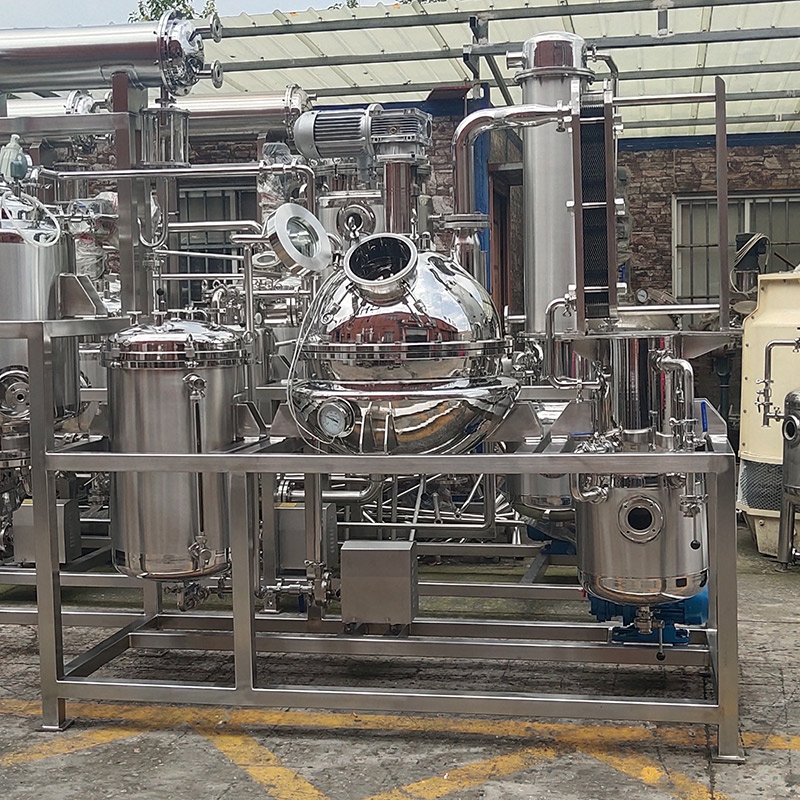

Zogulitsa

Chigawo chochotsa zitsamba

Kugwiritsa ntchito

wagawo izi ndi ophatikizana m'zigawo ndi ndende wagawo, amene angagwiritsidwe ntchito m'mayunivesite, mabungwe kafukufuku sayansi, zipatala, mabizinesi, etc. monga kutsimikiza kwa magawo atsopano mankhwala m'zigawo luso, mayesero wapakatikati, chitukuko cha mitundu yatsopano, zamtengo wapatali mankhwala m'zigawo, kosakhazikika mafuta kuchira, etc. wagawo ali ndi ntchito wathunthu, amene angathe kukwaniritsa zofunika m'zigawo m'zigawo, madzi m'zigawo zosakhazikika, mafuta odzola, mowa, hotflux, mafuta odzola, mafuta odzola, ndi zina zotero. ndipo akhoza kuchira zosungunulira organic. Mphamvu yokoka ya chotsitsa chokhazikika imatha kufika pa 1.3, ndipo khoma lamkati la concentrator silinaphike ndipo kutulutsa kumakhala kosalala. Magawo onsewa ali ndi zida zokwanira, zophatikizika, zazing'ono komanso zokongola m'mawonekedwe, zosavuta kugwiritsa ntchito ndikuwongolera, ndikukwaniritsa zofunikira kuti zigwiritsidwe ntchito pansi pamikhalidwe ya labotale. Kuphatikizirapo tanki yochotsa zinthu zambiri, cholumikizira cha vacuum decompression concentrator, pampu yovumbula yamadzi osaphulika komanso makina otenthetsera mafuta, komanso mapaipi onse ndi ma valve.

Mawonekedwe

1) Kuchuluka kwa zinthu zodyera. Kuchuluka kwa zida zodyera ndi nthawi imodzi kuposa mtundu wamba wa distillation.

2) Good luso kusinthasintha. Madzi kapena mowa zosungunulira distillation mu zinthu zoipa kuthamanga, kuthamanga yachibadwa ndi kukakamiza zabwino, makamaka otsika kutentha distillation wa kutentha tcheru zipangizo akhoza kupangidwa.

3) Kuchuluka kwamafuta-kusonkhanitsa. Chifukwa cha mphamvu distillation mankhwala zosungunulira zili mu mankhwala ndi zosungunulira amakhala mkulu gradient, amene kumawonjezera kukankhira mphamvu ya lixiviation ndi kumawonjezera mafuta-kusonkhanitsa rate.lt akhoza kuchotsa 5-20% kuposa njira yachibadwa.

4) Kupulumutsa zosungunulira. 30-50% mphamvu akhoza kutsirizidwa mu sitepe imodzi, ndipo ndende akhoza anamaliza mu sitepe imodzi, ndi re flux wa unit ndi wamkulu ndi nthawi imodzi kuposa wamba mtundu. Nthawi ya ndondomeko yonse ndi maola 4-6 okha.

5) Kugwiritsa ntchito mphamvu zochepa. Nthunzi yachiwiri imagwiritsidwa ntchito ngati gwero la kutentha.

6) Distillation ndi ndende zimatha kupangidwa nthawi imodzi. Kutentha kwa reflux condensing zakumwa kumakhala kofanana ndi kutentha kwamadzi mu distillation tank.

Foaming polyurethane ntchito ngati wosanjikiza kutentha kuteteza, ndi kutentha, digiri vacuum akhoza lizilamulira automatically. Mu unit, pamwamba pa 50% nthunzi imatha kupulumutsidwa.

Ubwino wake

Zalowa bwino pamsika wapadziko lonse lapansi chifukwa cha ntchito zambiri, magwiridwe antchito abwino, kapangidwe kake, komanso kupanga kwapamwamba. Amagwiritsidwa ntchito kwambiri poyesa kuyesa mu bungwe lofufuza zasayansi, yunivesite, koleji, fakitale; kapena kupeza mankhwala okwera mtengo.

| Kuchuluka kwa thanki yotulutsa (m³) | 1 | 2 | 3 | 4 | 5 | 6 |

| Kuchuluka kwa concentrator (kg/h) | 1000 | 1500 | 2000 | 2500 | 3000 | 3500 |

| Used pressure (Mpa) | 0.08-0.2 | |||||

| Digiri ya vacuum yogwiritsidwa ntchito (Mpa) | 0.05-0.08 | |||||

| Kutulutsa & kutentha kwambiri (°c) | 70-100 | |||||

| Kutulutsa & nthawi yokhazikika (maola / batch) | 4~5 pa | |||||